Sceleziona i prodotti:

Software di programmazione ProNC

ProNC

Il software universale per i nuovi controller isel

| Convenient

operating and programming interface Programming

according to isel PAL or DIN 66025 |

|

||||

ProNC is the integration of the control programmes Remote, implemented for the operating system MS-DOS by iselautomation, ProDIN and ProPAL into one software product as a new, powerful operating and programming interface under MS Windows (98, NT 4.x, 2000 and XP). All NC programs that were previously used by the operators for Remote (isel NCP format), ProDIN (DIN/ISO format) and/or ProPAL (isel PAL format) can be executed by ProNC. |

|||||

| ProNC consequently uses the MS Windows concept of dynamic linking (Dynamic Link Library = DLL) for the realization of the necessary module and/or device interfaces for the control of: |

|

|

|||

| ProNC

contains an extensive dialogue software for the configuration, parameterization,

start-up and diagnostics of numerical axes/systems including the necessary

periphery. The application range of ProNC covers automation solutions particularly in the areas assembly, handling, loading and quality inspection, in which the user programs are predominantly created textually by using teach-in functions and/or by integrating contour data records (e. g. isel NCP format). |

|||||

| To use ProNC efficiently for the purpose of start-up / optimization of the user programs, inter alia, the following characteristics were implemented: |

|

|

|||

|

|||||

| ProNC is an open software system. All interfaces are documented in the isel CNC API (Application Programming Interface). The activation of user software (as Windows EXE or Windows DLL) out of the NC program (DIN/ISO or PAL) is supported. | |||||

-------------------------------------------------------------------------------- |

|||||

|

Operating Panels with Buttons Starting,

interrupting and cancelling the user program |

||||

-------------------------------------------------------------------------------- |

|||||

|

Machine

Positions Setting, correcting and testing machine positions Access to symbolic machine positions in the ISO/PAL user program |

||||

-------------------------------------------------------------------------------- |

|||||

|

Axes

Actuation Manual axes actuation, alternatively in the first or second axis system Teach-in with function keys, mouse click or joystick Step-by-step mode (jog) or axis actuation, slantwise travel |

||||

-------------------------------------------------------------------------------- |

|||||

|

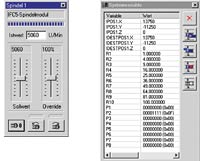

ProNC

System Monitor Axis status (limit switch) Speed indication Actual coordinates display Real variables (RX) Process variables (PX) Spindle Operating Panels |

||||

Input Support

File Types |

|

||||

| Source

file: |

user file in ISO syntax or PAL syntax | ||||

| Geometry file: | reading

and writing of machine positions e. g. via teach-in, in the set-up or automatic mode |

||||

| CNC target file: |

compiled source file in the CNC format as output file for the interpreter | ||||

| Error file : | list of the syntactic errors after the compiler run | ||||

| Variables file: |

reading of real variables at the program start and / or saving at the program end or abnormal termination or at run time of the user program |

||||

| MIstruzioni operative ProNC file PDF | ||

| Istruzioni di programmazione ProNC -file PDF | ||

| Depliant informativo del ProNC f ile PDF . |

Il gruppo Isel è rappresentato in Italia da technoLASA S.r.l.